The Accu-Cut tubing cutter uses computer control, innovative design and precise construction to quickly and accurately cut plastic, rubber, and elastomeric tubing.

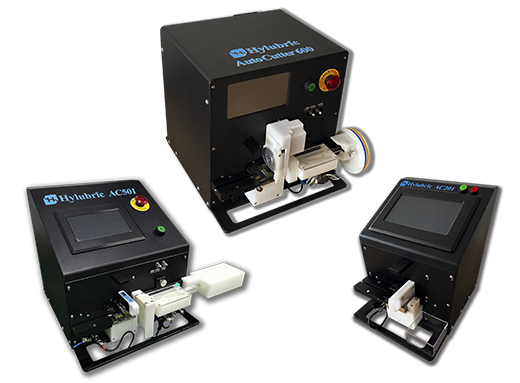

Automated Tube Cutting Systems

The Hylubric Accu-Cut tubing cutter uses computer control, innovative design and precise construction to quickly and accurately cut plastic, rubber, and elastomeric tubing.

The machine uses an industrial single edge razor blade, sliding in a narrow slot in a stainless steel dieset bushing. This tubing feeds through a hole in this bushing perpendicular to the blade slot that is sized and positioned to provide optimum cutting performance for a specific tubing diameter and hardness. The precise fit of the tubing in the bushing provides a very clean, square cut.

Features

· Auto Feeding Syste

· Burr-free cutting edge

· Precision cutting length

· Easy setup and tool change

· HMI with color touchscreen

· Uses standard, low cost blades

· Customizable for special requirements

· PU

· PVC

· PC

· PEEK

· RUBBER

· ELASTOMERIC TUBING

· HARD MATERIAL TUBING

Technical Data

Function | Description | AC201 | AC501 | AC600 |

Basic Specs | Machine Dimensions | 30cm x 24cm x 35cm | 50cm x 36cm x 50cm | 60cm x 36cm x 50cm |

Machine Weight | 10 kg | 30 kg | 30 kg | |

Rated Voltage | 88~264VAC | 90~264VAC | 90~264VAC | |

Frequency Range | 47~63Hz | 47~63Hz | 47~63Hz | |

Rated Current | 2.5A/115VAC, 1.5A/230VAC | 3.7A/115VAC, 2.4A/230VAC | 3.7A/115VAC, 2.4A/230VAC | |

Rated Power | 150W | 180W | 180W | |

Compressed Air | — | 0.6-0.8MPa | 0.6-0.8MPa | |

Temperature | -20~+60℃ | -20~+60℃ | -20~+60℃ | |

Humidity | 20~+95% RH | 20~+95% RH | 20~+95% RH | |

Cutting Unit | Equipped with high precision sensor and servo driving system | √ | √ | √ |

Equipped with replaceable driving roller | √ | √ | √ | |

Standard model with 0.020mm feed precision. Higher precision can be customized | √ | √ | √ | |

Uses replaceable slide block and cutting blades, can be customized | √ | √ | √ | |

Blow air to working area after each cutting, clean debris and detergent | — | √ | √ | |

Control Unit | HMI with color touchscreen | √ | √ | √ |

Working process in Graphical Display | √ | √ | √ | |

Alarm for process abnormal | √ | √ | √ | |

Auto Gap* | Equipped with Auto-Gap system | √ | √ | √ |

Auto-Gap system automatically adjusts gap based on material size | √ | √ | √ | |

Feed detect* | Inline feeding detector | √ | √ | √ |

Detected by non-contact optical fiber, will not affect the feeding process | √ | √ | √ | |

Receiving Boxes* | Receiving box holder for various boxes | √ | √ | √ |

Users can use various boxes to store and transfer tubes | √ | √ | √ | |

Box customizable | √ | √ | √ | |

Ion spray* | Optional ionic static electricity elimination device | — | √ | √ |

Ionic air works on feeding tubes to eliminate static electricity caused by feeding and cutting | — | √ | √ | |

Alcohol Spray* | Equipped with alcohol spray device | — | √ | √ |

Alcohol can be sprayed onto blade and working surface automatically | — | √ | √ | |

Use Alcohol on blades and tubes to lubricate, to cool and to sterilize | — | √ | √ | |

Alcohol is most commonly used, though other liquids and mixtures may also provide satisfying results | — | √ | √ | |

Trash Eject* | Trash eject system identifies first and last piece of tube | — | √ | √ |

Ejects waste tube into trash box | — | √ | √ | |

Data Communications* | Equipped with serial port and network communication functions | √ | √ | √ |

Remote monitoring and controlling | √ | √ | √ |

Remarks:*for optional. Customized for special requirements.

For a timely response, go to Online enquiry or contact us.

Technical Data

Function | Description | AC201 | AC501 | AC600 |

Basic Specs | Machine Dimensions | 30cm x 24cm x 35cm | 50cm x 36cm x 50cm | 60cm x 36cm x 50cm |

Machine Weight | 10 kg | 30 kg | 30 kg | |

Rated Voltage | 88~264VAC | 90~264VAC | 90~264VAC | |

Frequency Range | 47~63Hz | 47~63Hz | 47~63Hz | |

Rated Current | 2.5A/115VAC, 1.5A/230VAC | 3.7A/115VAC, 2.4A/230VAC | 3.7A/115VAC, 2.4A/230VAC | |

Rated Power | 150W | 180W | 180W | |

Compressed Air | — | 0.6-0.8MPa | 0.6-0.8MPa | |

Temperature | -20~+60℃ | -20~+60℃ | -20~+60℃ | |

Humidity | 20~+95% RH | 20~+95% RH | 20~+95% RH | |

Cutting Unit | Equipped with high precision sensor and servo driving system | √ | √ | √ |

Equipped with replaceable driving roller | √ | √ | √ | |

Standard model with 0.020mm feed precision. Higher precision can be customized | √ | √ | √ | |

Uses replaceable slide block and cutting blades, can be customized | √ | √ | √ | |

Blow air to working area after each cutting, clean debris and detergent | — | √ | √ | |

Control Unit | HMI with color touchscreen | √ | √ | √ |

Working process in Graphical Display | √ | √ | √ | |

Alarm for process abnormal | √ | √ | √ | |

Auto Gap* | Equipped with Auto-Gap system | √ | √ | √ |

Auto-Gap system automatically adjusts gap based on material size | √ | √ | √ | |

Feed detect* | Inline feeding detector | √ | √ | √ |

Detected by non-contact optical fiber, will not affect the feeding process | √ | √ | √ | |

Receiving Boxes* | Receiving box holder for various boxes | √ | √ | √ |

Users can use various boxes to store and transfer tubes | √ | √ | √ | |

Box customizable | √ | √ | √ | |

Ion spray* | Optional ionic static electricity elimination device | — | √ | √ |

Ionic air works on feeding tubes to eliminate static electricity caused by feeding and cutting | — | √ | √ | |

Alcohol Spray* | Equipped with alcohol spray device | — | √ | √ |

Alcohol can be sprayed onto blade and working surface automatically | — | √ | √ | |

Use Alcohol on blades and tubes to lubricate, to cool and to sterilize | — | √ | √ | |

Alcohol is most commonly used, though other liquids and mixtures may also provide satisfying results | — | √ | √ | |

Trash Eject* | Trash eject system identifies first and last piece of tube | — | √ | √ |

Ejects waste tube into trash box | — | √ | √ | |

Data Communications* | Equipped with serial port and network communication functions | √ | √ | √ |

Remote monitoring and controlling | √ | √ | √ |

Remarks:*for optional. Customized for special requirements.