· Round, Flat, Square or Special Shapes

· Stainless Steels (302, 304, 316 L & LVM)

· Precipitation Hardenable Stainless Steel (17/4, 17/7)

· Cobalt & Moly Alloys (MP35N, 35NLT, Elgiloy & ASTM F1058)

· Precious Metals (Platinum, Palladium, Gold, Silver, others)

· Nitinol (Superelastics & Shape Memory)

· Beryllium Copper, Phosphorus Bronze

· Tungsten, Titanium

· Coated Materials and Exotic Alloys

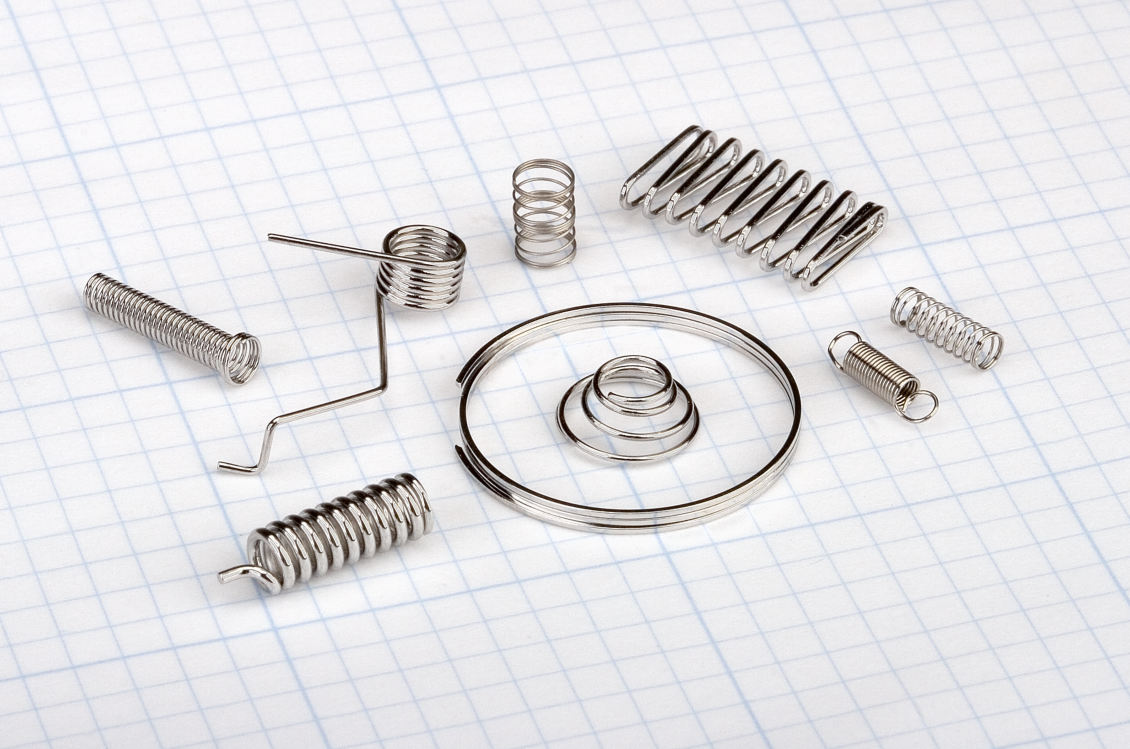

Coil & Spring

Round, Flat, Square or Special Shapes

Precision Capabilities

· CNC Point Deflection Coiling (Compression, Torsion and Extension Springs)

· Mandrel Winding

· CNC Wire Forming

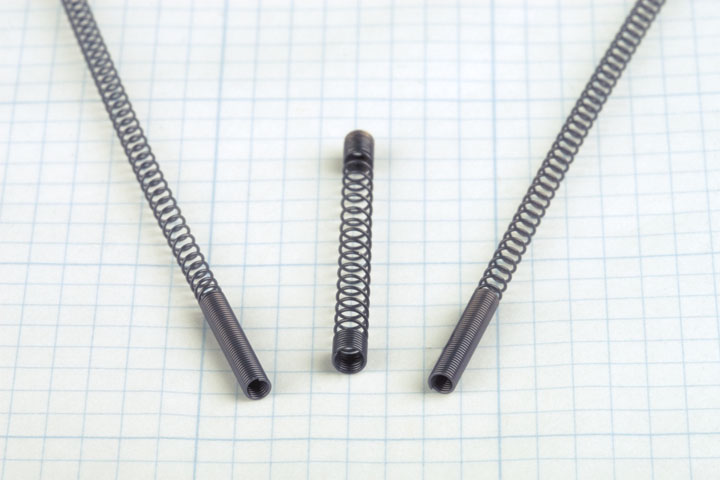

· Wire Sizes (0.0007" to 0.080")

· Coil outside diameters down to 0.0050"

· Conical Springs

· Variable Pitch and Diameter

· Magazine Springs

Materials

· (Round, Flat, Square or Special Shapes)

· Stainless Steels (302, 304, 316 L & LVM)

· Precipitation Hardenable Stainless Steel (17/4, 17/7)

· Cobalt & Moly Alloys (MP35N, 35NLT, Elgiloy & ASTM F1058)

· Precious Metals (Platinum, Palladium, Gold, Silver, others)

· Nitinol (Superelastics & Shape Memory)

· Beryllium Copper, Phosphorus Bronze

· Tungsten, Titanium

· Coated Materials and Exotic Alloy

We offer special processing capabilities to support and add value to our core capabilities.

Special Support Capabilities

· Laser Welding

· Point/Tip Grinding

· Coil End Grinding

· Abrading

· Coated and Plated Components

· Ultrasonic Cleaning, Special Cleaning Processes

· Passivation (ASTM A 967)

· Chemical Oxide Removal and Etching

· Heat Treating (inert and air atmosphere)

Motion Dynamics is known for manufacturing some of the smallest wire components in the world including high precision laser welded Micro Garter Springs. We are capable of utilizing wire diameters down to 0.0007" and producing coil diameters down to 0.005." Micro Garter inside diameters <0.100."

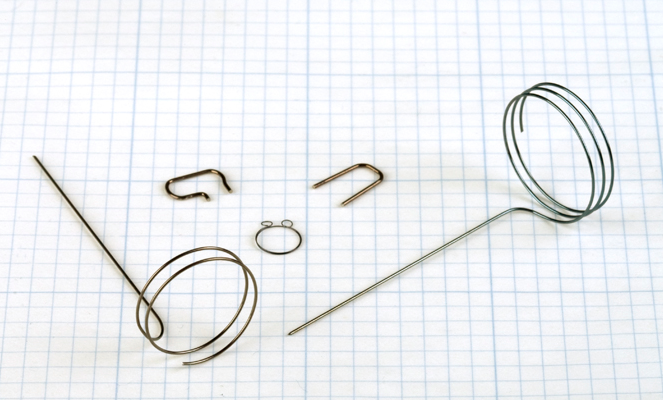

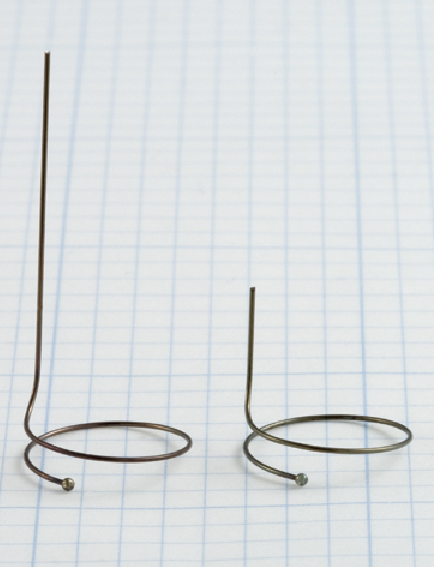

Micro Coiling and Forming

· Compression Springs

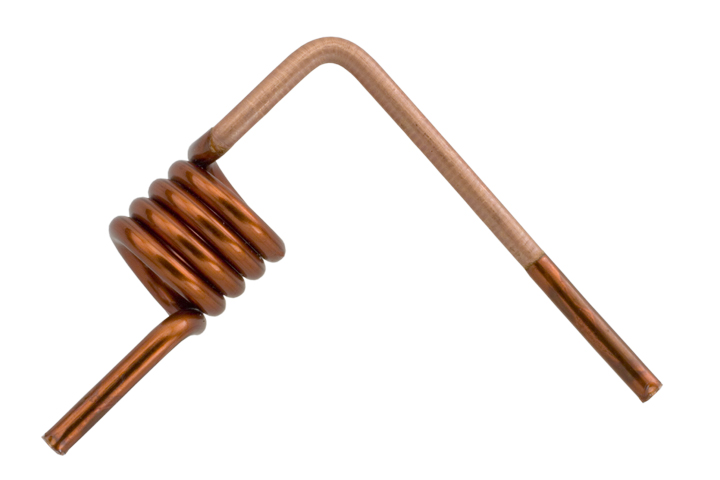

· Torsion Springs

· Extension Springs

· Complex Wire Forms

· Micro Garter Springs (garter inside diameters <0.100")

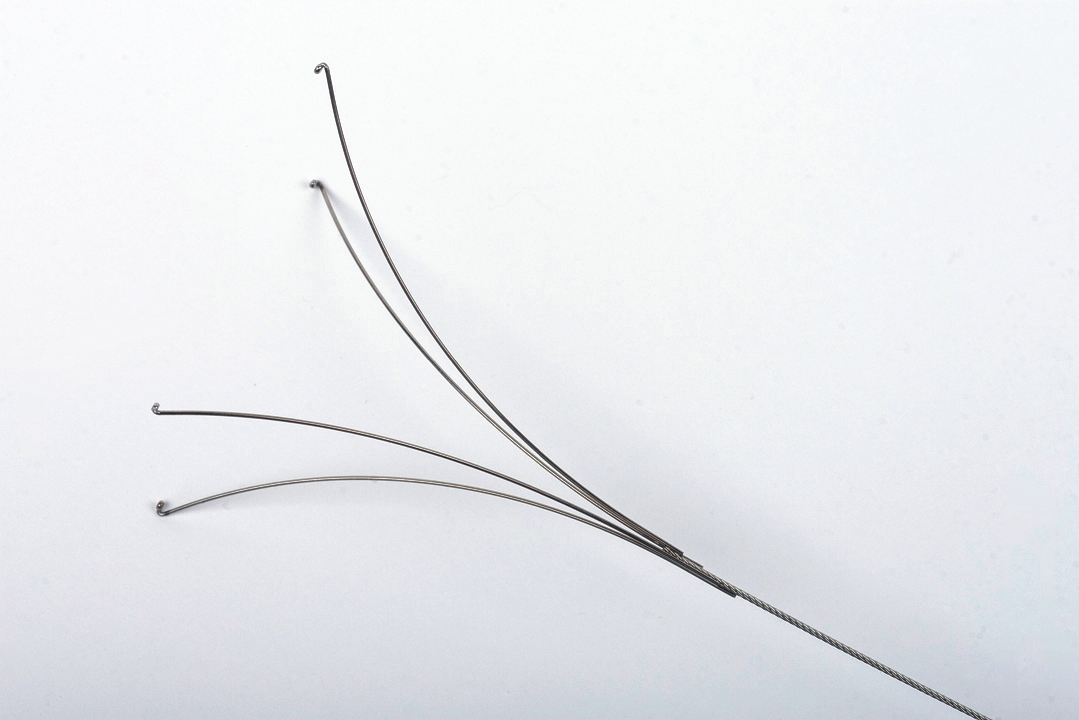

Motion Dynamics has invested considerable resources in recent years, both in engineering personnel and state-of-the art equipment in order to excel as a supplier of high precision and complex nitinol components. We offer both Superelastic and Shape Memory temperature activated components.

Nitinol Forms, Coils and Springs

· Compression, Torsion and Extension Springs

· Precision Wire Forms

· Laser Welded Nitinol Assemblies

· Design Assistance

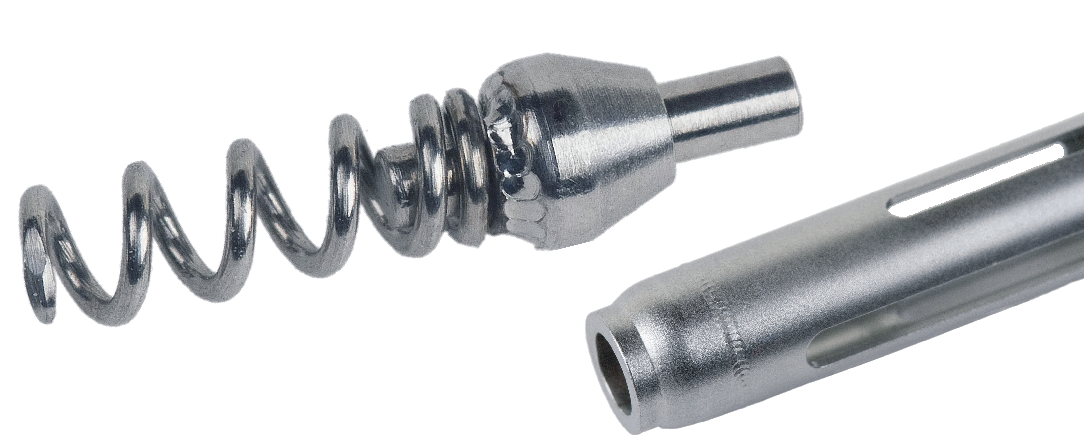

Laser welding processes have been added to offer even more value to the wire components we provide including the precise assembly of multiple components.

Laser Welding

· Seam, Butt and Penetration Welds

· Tip Radius and Ball Tip Formations

· Spot Welds <0.002"

· Weld Validations via Beam Energy and Pull Testing

Many micro wire components are combined with others to produce an assembly for specific devices and applications, specifically medical device and cardiac catheter applications.

Wire Assemblies

· Components Laser Welded and Attached

· Multiple Component Materials Combined

· Heat Shrink and Jacket Installations

· Wire Sub-Assemblies

· Complex Combinations of Coils, Tubing, Wires and Machined Components

Nobilis Metals是贵金属制造商,是伯克希尔•哈撒韦全资品牌,拥有100多年贵金属制造经验。可加工黄金、银、钯、铂、铜镀金、焊锡合金以及各种贵金属合金。生产包括丝材、管材、棒材、板材、铝箔、锡焊合金、铸造材料和组件等